During the processing of an ore into metal, various residues are produced both in the processing and in the subsequent metallurgical steps, such as tailings, slags, dusts, leaching residues and precipitation products. These often contain economically interesting enrichments of different metals, the composition of which, however, is usually very complex. The characterization of the residual materials is therefore of prime importance to optimally adapt the processes to the starting material, enabling a profitable extraction of the metals. To determine significant contents of valuable metals, bulk analysis by X-ray fluorescence analysis (XRF) or ICP-MS (mass spectrometry with inductively coupled plasma) is necessary. If valuable metals are present in significant amounts, the following questions must be clarified in detail:

During the processing of an ore into metal, various residues are produced both in the processing and in the subsequent metallurgical steps, such as tailings, slags, dusts, leaching residues and precipitation products. These often contain economically interesting enrichments of different metals, the composition of which, however, is usually very complex. The characterization of the residual materials is therefore of prime importance to optimally adapt the processes to the starting material, enabling a profitable extraction of the metals. To determine significant contents of valuable metals, bulk analysis by X-ray fluorescence analysis (XRF) or ICP-MS (mass spectrometry with inductively coupled plasma) is necessary. If valuable metals are present in significant amounts, the following questions must be clarified in detail:

- Which phases contain the required elements, both valuable metals and impurities?

- In what quantity do the identified carrier phases occur?

- What is the morphology of the components?

- How are the phases intergrown?

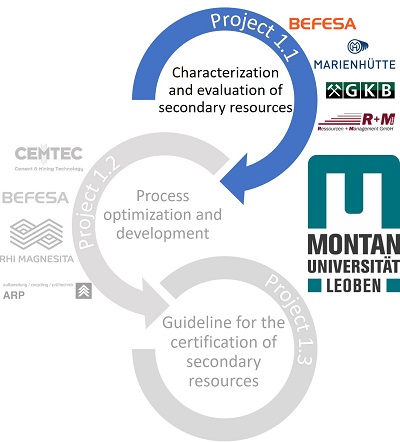

Depending on the starting material, incident light microscopes, scanning electron microscope (SEM) or electron microprobe (EMP) are available. Based on this information, suitable processing methods can be selected, developed and evaluated in project 1.2.